How to Use Color Thermal Labels to Organize Your Business

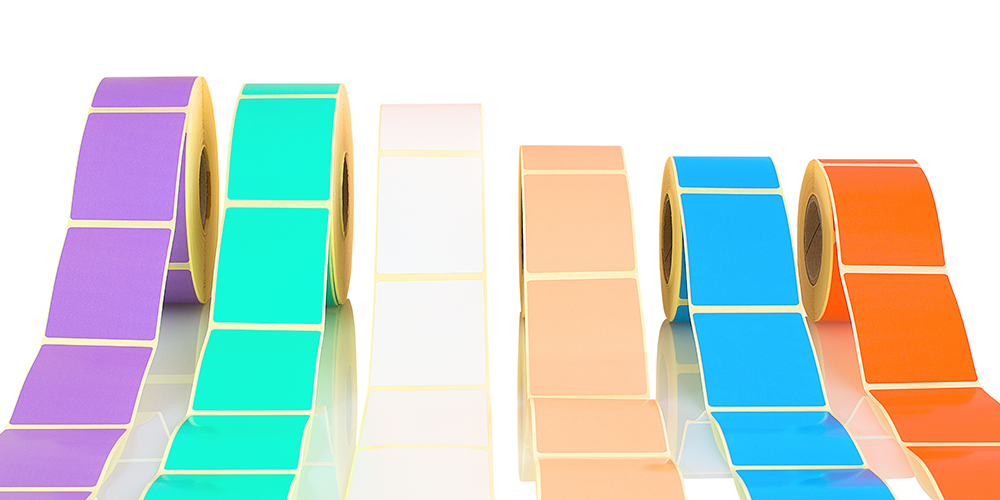

Color thermal labels are a simple way to help your team stay organized. Whether you're tracking inventory, managing paperwork, or keeping things moving on the floor, adding color makes it easier to spot what’s what—fast. A good color-coded system can cut down on mistakes and help things run more smoothly day to day.

In this article, we’ll walk through how to use color thermal labels in your business, share some common use cases, best practices, and a few things to avoid.

1. How Businesses Use Color Thermal Labels

Warehouses & Inventory Management

- Assign different colors to product categories, SKUs, or storage zones for faster identification.

- Use green for in-stock items, yellow for low stock, and red for out-of-stock products.

- Speed up cycle counts by using color-coded bin labels.

Retail & Pricing

- Use color labels for discount categories—red for clearance, blue for seasonal sales.

- Label products by size or type using a consistent color scheme.

- Mark perishable goods with colored expiration date labels to prevent waste.

Healthcare & Medical Offices

- Categorize patient records, prescriptions, or lab samples using different label colors.

- Use color-coded appointment labels for quick scheduling reference.

- Improve medication safety by using different colors for dosages or allergy warnings.

Food & Beverage

- Assign colors to different allergens to prevent cross-contamination.

- Label batch numbers and expiration dates for better inventory rotation.

- Use blue for seafood, green for organic items, and red for high-priority orders.

Manufacturing & Logistics

- Mark production stages with color thermal labels to track work-in-progress orders.

- Assign shipment priority levels using color labels—urgent orders in red, standard shipments in blue.

- Use color barcodes for batch tracking and defect labeling in quality control.

2. Best Practices for Designing Color Thermal Labels

Choosing the Right Colors for Organization

- Stick to five or fewer colors to avoid confusion.

- Use high-contrast text and barcodes for readability.

- Establish a consistent color code across departments for easy recognition.

Formatting Text and Barcodes for Clarity

- Use bold, sans-serif fonts in at least 12 pt size for clear printing.

- Keep barcodes at least 300 dpi for accurate scanning.

- Include white space around barcodes to prevent scanning errors.

Preventing Fading and Smudging

- Use thermal transfer labels with resin ribbons for long-lasting color prints.

- Store labels away from heat and direct sunlight to prevent fading.

- Choose water-resistant and smudge-proof label materials for durability.

3. Printing Color Thermal Labels the Right Way

Direct Thermal vs. Thermal Transfer Color Labels

- Direct thermal labels are cost-effective but fade over time. Best for short-term use (e.g., shipping, temporary labeling).

- Thermal transfer labels use colored ribbons, producing longer-lasting prints for inventory, signage, and asset tracking.

Setting Up Your Printer for Accurate Color Labels

- Adjust color density settings to match label material.

- Use compatible thermal transfer ribbons for vibrant, smudge-resistant prints.

- Perform test prints before large runs to ensure colors appear correctly.

Common Printing Issues and Fixes

- Labels printing too light? Increase print heat settings and use a higher-quality ribbon.

- Barcodes not scanning? Ensure sharp contrast and remove any overlapping graphics.

- Smudging or streaking? Check that the ribbon and label materials are compatible.

4. Mistakes to Avoid When Using Color Thermal Labels

-

Overcomplicating the Color System

Too many colors can lead to confusion—stick to a simplified, logical system. -

Using Low-Quality Labels That Fade Quickly

Choose heat-resistant and smudge-proof label materials for durability. -

Inconsistent Labeling Across Departments

Standardize color assignments and label formatting across teams. -

Not Training Employees on the Labeling System

Create a reference guide for staff to follow color-coding rules accurately.

5. Choosing the Right Color Thermal Labels for Your Business

Factors to Consider

- Material – Use direct thermal for short-term needs, thermal transfer for long-lasting labels.

- Adhesive type – Permanent for inventory tracking, removable for temporary use.

- Printer compatibility – Ensure labels match your thermal printer model.

Best Places to Use Color Thermal Labels

- Shelving & bin labels for fast stock identification.

- Shipping & packaging labels to highlight order priorities.

- Office organization labels for easy document tracking.

Organize Smarter with Color Thermal Labels

A well-planned color labeling system simplifies organization, reduces errors, and improves efficiency across industries. Whether managing inventory, pricing, or medical records, color thermal labels help businesses stay organized and productive.

If you're looking for durable and vibrant labels, check out Label Blanks and shop our selection of color thermal labels designed for long-term business use.

Frequently Asked Questions

How do I choose the right colors for thermal labels?

Stick to a simple, clear color system based on functionality—for example, red for urgent items, green for in-stock, and yellow for low stock. Avoid using too many colors, which can cause confusion.

Can I print color thermal labels on a regular thermal printer?

Most standard thermal printers print only in black, but thermal transfer printers allow for full-color labels using colored ribbons.

What type of thermal labels last the longest?

Thermal transfer labels last the longest, especially when paired with resin-based ribbons. These resist fading, smudging, and heat damage better than direct thermal labels.

Why are my color thermal labels fading quickly?

Direct thermal labels can fade if exposed to heat, light, or moisture. Switching to thermal transfer labels or using a protective overcoat can help extend their lifespan.

How can I prevent barcode scanning issues on color labels?

Ensure barcodes are at least 300 dpi, use high-contrast colors, and leave enough white space around them. Testing barcodes before full-scale printing can catch issues early.